Power semiconductor devices can be divided into several types by their design. They can be assembled as a stud, capsule, or module. Recently, solutions integrating the power semiconductor device, cooling system, and circuit control into a single unit have also become very popular in the power electronics industry.

Diodes and Thyristors. Stud Design

The stud type housings assume a threaded attachment of the power semiconductor device to the heatsink, providing both the installation of the device and cooling during its operation. For relatively low power devices, designed, as a rule, for currents less than 50 A, a design is used that provides for soldering a semiconductor element to the baseplate.

To compensate for the thermomechanical stresses arising due to differences in junction temperature, soldering is used through an intermediate thermal compensator made of a material with a value close to silicon junction temperature. This is molybdenum or tungsten. Despite this, when the size of a semiconductor element is more than 15 mm, there are problems with the stability of soldered joints to thermal cycles.

Therefore, the use of such a design is limited to relatively low current devices. For high current devices, a design with an internal clamp of a semiconductor element is used.

Devices in stud design are easy to install, but their design imposes significant restrictions on the permissible average current of the device and the blocking voltage. Due to the limitation of the maximum allowable diameter of the semiconductor crystal and the rather significant thermal resistance of the junction to housing, the permissible average current of such devices does not exceed 400 A. The complex design with an internal clamp does not allow to obtain large spark gaps between the parts of the housing galvanically connected to the anode and cathode. This leads to a limitation of the blocking voltage at a level, as a rule, not higher than 2000 V.

Diodes and Thyristors. Capsule Design

The use of capsule-shaped housings allows avoiding these limitations. This design is sometimes called a tablet, disc, hockey puck, etc.

A semiconductor element consisting of a silicon crystal connected to a thermal compensator disc is located between the cathode and anode copper clamping baseplates through which electrical contact and cooling are carried out. To improve the thermal and electrical properties, the contact of the semiconductor element with the baseplates is usually carried out through silver gaskets. To increase power cycling, the cathode gasket is often made of molybdenum.

External electrical insulation between the cathode and the anode is provided by a ceramic ring. The tightness of the housing is provided by membrane copper flanges soldered to the cathode and anode baseplates, as well as to the ceramic ring. The internal alignment of the semiconductor element in the housing is carried out by an insulating ring. The contact to the control electrode is a pressure one, carried out by a spring through an insulating insert.

To center the housing in the external clamping device, the anode and cathode baseplates are provided with recesses. In contrast to the devices of the stud design, for the operation of the capsule power semiconductors, an external clamping device is required that provides the necessary mounting force between the clamping contacts.

Devices of the capsule design are absolute record holders in terms of permissible switching power. There have been developed designs that allow placing semiconductor elements with a diameter of up to 150 mm, if necessary, and the standard range can be easily expanded to use even larger semiconductor elements. Effective double-sided cooling is the most effective among all other designs.

The simple and reliable insulation design between the anode and the cathode allows to package devices with a voltage of up to 12 kV and has no difficulties if it is necessary to increase the blocking voltage. The capsule power semiconductors are well assembled into series high voltage stacks. The low inductance of the housing allows the effective use of capsule semiconductors in pulse power equipment.

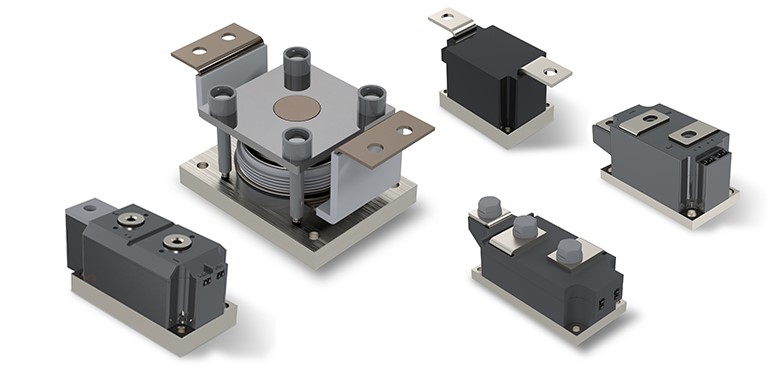

Diodes and Thyristors. Modular Design

Devices in modular design have a number of advantages that explain the growth of their popularity among manufacturers of power semiconductors and power electronics equipment:

- they are easy to install

- and it is possible to implement an entire unit of equipment in a single module that includes several semiconductor devices as part of a complex electrical circuit

All the types of power semiconductor devices mentioned above are available in a modular design, while the design concepts used, despite the difference in the types of power semiconductor devices, are highly standardized.

Thus, the design of soldered modules based on MOSFETs are almost identical to those based on IGBT. Soldered modules based on thyristors and diodes are also similar in design to MOSFET and IGBT modules.

The modules based on diodes and thyristors can be divided into two types according to the design concept and manufacturing technology:

- power semiconductor modules with solder contact technology of semiconductor elements

- power semiconductor modules with pressure contact technology of semiconductor elements

The soldered modules have a design similar to the IGBT modules of standard design. Modules of this type are produced, as a rule, for currents less than 100 A, voltages up to 2000 V.

Power semiconductor modules with pressure contact technology of a semiconductor element are available for higher power equipment and have an average current of up to 1000 A with blocking voltage up to 6500 V. Due to the use of a pressure contact design, such power semiconductor modules have an increased power cycling reliability. Similar to the stud power semiconductor devices, the internal clamping is carried out through the use of special elastic elements.

Learn more about power semiconductors in Power Semiconductors section of my Marketing Psycho blog. And if you are interested in power semiconductors market news, you can always subscribe to my Power Semiconductors Weekly updates.

Power Semiconductors Weekly is a Marketing Psycho weekly podcast covering the latest news from power semiconductors industry. Delivered to you every Tuesday by Alexey Cherkasov, Power Semiconductors Weekly brings you the most interesting events in the world of power semiconductors and power electronics. Subscribe to Power Semiconductors Weekly and watch it on YouTube every Tuesday.

If you prefer a monthly update about the world of power semiconductors delivered to your e-mail address, please, subscribe to Marketing Psycho Power Semiconductors newsletter.