Power Semiconductors Weekly Vol. 103

Leapers Semiconductor Delivers Highest Power Density Ultra Compact SiC Power Modules on the Market

Rapid growth of technology over the past century brought as many advantages as many disadvantages including the accelerating global warming with its dramatic consequences we face every day in various parts of our planet. So far no one found the solution how to stop this process, but there are many solutions how to slow it down. This is why the modern society responds to this challenge with its zero emissions carbon free initiatives launched in many countries across the globe. And one of the major steps in this green society program is electrification of passenger and commercial vehicles.

Right now, companies have various approaches to vehicle electrification like mild-hybrid electric vehicles MHEV, full hybrid electric vehicles HEV, plug-in hybrid electric vehicles PHEV, battery electric vehicles BEV, and fuel-cell electric vehicle FCEV.

Recently a lot of attention has been paid to fuel-cell electric vehicles, FCEVs. The existing FCEVs generally use the external energy systems like high-voltage battery packs as the auxiliary power source to improve the dynamic characteristics of the system. Among them, the DC-DC controller converts the output voltage of the FCEVs to a level that matches the DC bus voltage and adjusts the output power of the FCEVs according to the power demand of the vehicle and the SOC state of the battery pack or supercapacitor. Therefore, the DC-DC controller of the FCEVs is the key component in the power system.

The application environment of the DC-DC controller is relatively special, especially in the conditions of high frequency (≥ 50kHz), high current (output 100-300A), high voltage (output voltage 300-800V) and high integration. And the traditional IGBT cannot meet these requirements, so SiC is the most suitable solution for this scenario because of its characteristics of high frequency, high voltage withstand, low conductivity, and low switching losses.

According to the test data, at different frequencies, the efficiency of the converter built with SiC is 1% – 3.1% higher compared to the same built with Si. These efficiency improvements can significantly reduce the overall operating cost of the FCEVs for the same mileage, which is very significant improvement for the production and use of FCEV.

To further enhance the efficiency of the FCEVs, Leapers Semiconductor has expanded its E0 family of the automotive grade SiC power modules with the most powerful version ever produced in such a compact package.

The new DFS09CU12EYQ1 SiC power module delivers high power density which is specifically beneficial for FCEV power system. Boost circuit topology can support the maximum 150A current output, while the same package commercially available modules can only achieve 100A current output.

Among the other features of the new E0 DFS09CU12EYQ1 SiC power module:

- Blocking voltage 1200V

- Rds(on)=9.2mW

- Maximum effective current 150A

- Rth(j-c)=0.09K/W

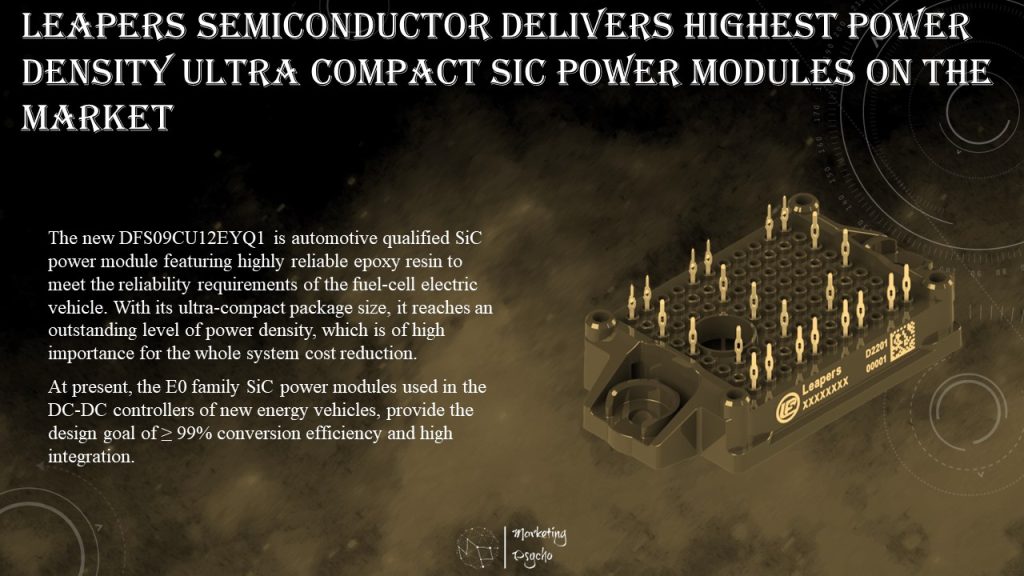

The new DFS09CU12EYQ1 is automotive qualified SiC power module featuring highly reliable epoxy resin to meet the reliability requirements of the fuel-cell electric vehicle. With its ultra-compact package size, it reaches an outstanding level of power density, which is of high importance for the whole system cost reduction.

At present, the E0 family SiC power modules used in the DC-DC controllers of new energy vehicles, provide the design goal of ≥ 99% conversion efficiency and high integration.

Besides the FCEVs application, the new DFS09CU12EYQ1 SiC power modules will be a perfect choice for:

- Frequency converters

- Photovoltaic energy storage systems

The samples of the new DFS09CU12EYQ1 SiC power modules produced by Leapers Semiconductor can be ordered starting today.

PANJIT Introduces New High Voltage FRED for Various Power Systems

Choosing the proper power diode for power applications is crucial for achieving high efficiency. PANJIT International Inc. has released power FREDs with the voltage range of 600V-1200V and current rating of 8A-60A.

With the outstanding trade-off performance of PANJIT FREDs, power system efficiency can be maximized. PANJIT FREDs are suitable for rectification or freewheeling circuits in various power applications.

Features:

- Best trade-off on Vf & Trr

- Low leakage current

- Soft recovery characteristic for better EMI

- Best efficiency achievable

- Best combination with power switches

Daxin Semi Sets up a 6-inch IGBT Production Line

Daxin Semi (达新电子), a Chinese IGBT provider, started construction of its 6-inch IGBT production line project in Fuling district of southwestern China’s Chongqing City.

With RMB2 billion ($290 million) investment, the new project will build a 6-inch power semiconductor wafer production line with special processes and an annual output of 1.2 million units. It will provide devices to sectors including new energy vehicles, smart grids, photovoltaic energy storage, wind power generation, industrial applications, and home appliances.

Founded in 2013, Daxin Semi has a chip design center in Shanghai and an IGBT module production line in Hangzhou. Its head office is in Yuyao of Ningbo, eastern China’s Zhejiang Province.

AdvanSiC Brings Together 11 Entities to Produce, Test and Validate Cost-Effective HV SiC MOSFETs

The European project AdvanSiC (Advances in Cost-Effective HV SiC Power Devices for Europe’s Medium Voltage Grids) has brought together 11 entities to produce, test and validate cost-effective High Voltage Silicon Carbide (SiC) MOSFET semiconductors in various Medium Voltage DC grid applications. The aim is to minimize HV SiC device cost by advancing novel design structures and process optimization.

The objective of AdvanSiC is to develop, produce, test, and validate cost-effective HV SiC MOSFET semiconductors in MVDC grid applications, a full-scale wind converter, a full-scale solar inverter, and a solid-state circuit breaker for DC converter stations.

The aim is to minimize HV SiC device cost by advancing novel design structures and process optimization. Beyond this, AdvanSiC will assure an immune and reliable environment to handle SiC fast transients, as well as optimize passives and cooling system to provide cost reduction not only at device level but also at system level.

The goal of AdvanSiC is to provide industrial leadership in key and emerging technologies to SMEs, start-ups, and industry from Europe to Europe, specifically in a technology that will be key to provide clean and affordable energy.

PowerAmerica Annual Meeting

Join PowerAmerica’s 2023 Annual Meeting at NC State University, on Centennial Campus, in Raleigh, NC, February 28 to March 2, 2023.

The two-and-a-half-day gathering of leaders and experts in silicon carbide (SiC) and gallium nitride (GaN) technology will offer networking sessions, keynote remarks, industry perspectives, student poster sessions and PowerAmerica project updates. Engineering and business development professionals are especially encouraged to attend.

Access the agenda here – meeting agenda.

Subscribe to Power Semiconductors Weekly and watch it on YouTube every Tuesday.

If you prefer a monthly update about the world of power semiconductors delivered to your e-mail address, please, subscribe to Marketing Psycho Power Semiconductors newsletter