Power Semiconductors Weekly Vol. 15

TSMC Supplier Expects To Equip U.S. Chip Plant In September Next Year

The Taiwan Semiconductor Manufacturing Company’s (TSMC) plans to establish a semiconductor fabrication plant inside the United States moved forward as its cleanroom equipment supplier received a contract qualification for the facility. TSMC plans to establish a new chip factory in Arizona, which will be capable of manufacturing semiconductors on the currently leading-edge 5nm process node. Jiangxi Hantang System Integration Co., Ltd, known to supply TSMC equipment for its fab, revealed the details in a conference, with executives emphasizing the costs of building chip facilities in the U.S.

According to Hantang, it should start installing equipment in the Arizona fab by September next year. This estimate is based on the company’s previous experience of dealing with TSMC and other customers, with orders from the Taiwanese fab yet to be finalized. It expects orders for the equipment to be finalized by July, with plant construction expected to commence by the end of this year.

Yes Power Technix to Receive SiC Trench MOSFET Tech

Yes Power Technix, a subsidiary of YEST, will receive silicon carbide (SiC) trench MOSFET technology from the Korea Electrotechnology Research Institute (KERI) for 2 billion won.

The technology was developed by KERI. South Korea is the third country after Japan and Germany to develop the technology.

SiC trench MOSFET forms a “trench” on the wafer. Current channels are placed on the vertical sides of this trench.

This reduces the surface channels take up then conventionally (they are usually placed horizontally), which allows power devices to become smaller.

Yes Power Technix said the technology will allow more chips to be produced per wafer, which will lead to lowered prices in power devices.

This will ultimately contribute in lowering the prices of electric cars, the company added.

There is currently a shortage in SiC power management chips for electric cars. Yes Power Technix said it will use the technology it received from KERI to make it a core business going forward.

Foxconn in Talks to Buy Chip Plant to Support EV Ambitions

Key Apple provider Foxconn confirmed it’s in talks to purchase a chip manufacturing plant from a number one Taiwanese reminiscence chipmaker, a transfer aimed toward securing sources for its electrical car enterprise amid the worldwide semiconductor provide crunch.

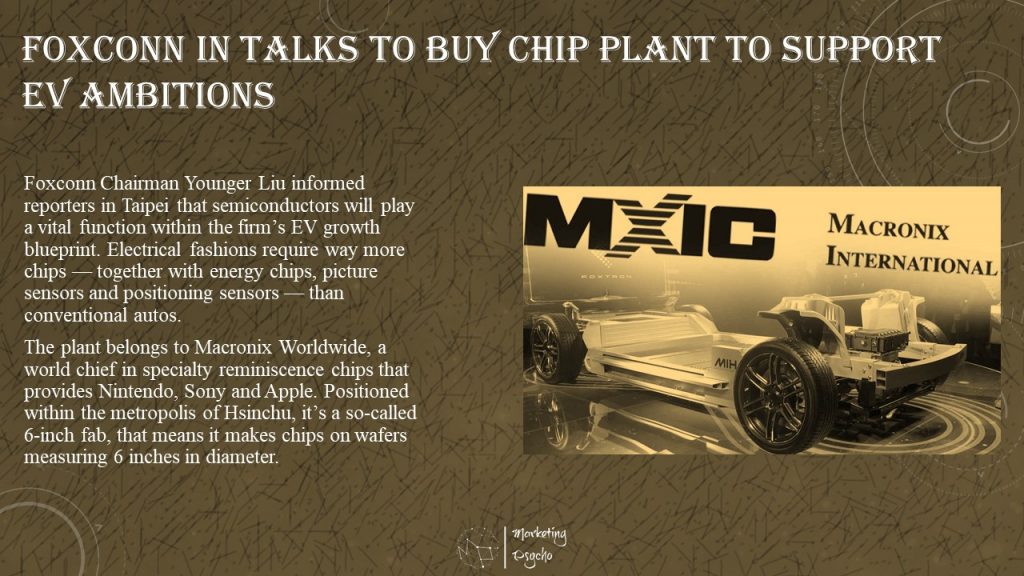

Foxconn Chairman Younger Liu informed reporters in Taipei that semiconductors will play a vital function within the firm’s EV growth blueprint. Electrical fashions require way more chips — together with energy chips, picture sensors and positioning sensors — than conventional autos.

The plant belongs to Macronix Worldwide, a world chief in specialty reminiscence chips that provides Nintendo, Sony and Apple. Positioned within the metropolis of Hsinchu, it’s a so-called 6-inch fab, that means it makes chips on wafers measuring 6 inches in diameter.

Foxconn’s push into semiconductors comes because the chip and element crunches have disrupted industries starting from smartphones and residential home equipment to cars.

Taiwan to Launch Programs to Expand Semiconductor Workforce

The Taiwanese government is planning to launch new policies aimed at helping the country’s semiconductor industry recruit sufficient workforce.

Concerted efforts will be made by the education, technology and economics ministries to introduce various programs starting third-quarter 2021 to help schools and other academic institutions produce 10,000 engineers for the semiconductor industry each year.

Currently, revenues generated by Taiwan’s electronics sector only contribute around 30% of the entire manufacturing industry’s overall sales, but in terms of fixed assets investments, it accounts for over 60% and in terms of R&D expenses, nearly 80%.

This indicates that Taiwan has been making heavy investments in order to keep its competitiveness in the global ICT market, particularly in the semiconductor segments.

Construction of Cree Site Nears Completion

Construction of Cree’s new $1 billion facility in Marcy is almost complete.

“The FAB is going to be substantially completed, at least the exterior by hopefully June July of this year, it’s a longer process than just that,” Nick Bruno, Associate Vice President-Business Development at Mohawk Valley EDGE explained. “They got to go into a tool install, where they’ll start ramping up and putting tools into the FAB and that’s going to be another longer process, so hopefully by the end of 2021 you’re going to start seeing some product coming out, test product and then they’ll be ultimately able to supply their customers by 2022.”

The chip manufacturing company began building its Marcy site in 2019, to increase the companies influence in the semiconductor business. The Mohawk Valley FAB will be the world’s largest silicon carbide device manufacturing facility.

II-VI Incorporated Inaugurates Technology and R&D Center in Shanghai

II‐VI Incorporated, a global leader in engineered materials and optoelectronic components, inaugurated the II-VI Technology and R&D Center in Shanghai, China. A grand opening ceremony was held with speakers, live entertainment, and facility tours.

The Center is II-VI’s largest technology and R&D hub, with nearly 600 employees. The Center will leverage its broad base of talent, including its senior scientists and engineers, to be a world leader in technology and product development, designing the most advanced optical components, subassemblies, and systems, and enabling customers around the world to serve rapidly growing new markets. These leading-edge innovations will unlock the further potential of the Cloud and 5G networks; integrated solutions for life sciences, including in biotechnology, medical, and scientific applications; and high-power lasers for materials processing and additive manufacturing.

“We are proud of this milestone event, which happily is taking place during our company’s 50th anniversary year and so it gives us another reason to celebrate,” said Dr. Vincent D. Mattera, Jr., CEO of II-VI Incorporated. “The Technology and R&D Center in Shanghai will be a jewel in the crown for II-VI’s worldwide innovation initiatives, focusing on key mega market trends where II-VI will continue to have a significant impact.”

The Center’s inauguration comes on the heels of II-VI’s announcement that it expanded its silicon carbide manufacturing footprint to China to serve the largest worldwide market for electric vehicles. II-VI maintains a large manufacturing operations and product development presence in China in the cities of Fuzhou, Guangzhou, Shanghai, Shenzhen, Suzhou, and Wuxi, where more than half of II-VI’s 22,000 employees are located.

Benefits of Using Silicon Carbide in Next Generation Programmable Power Test Solutions

Join this webinar to learn many benefits of using silicon carbide (SiC) technology to create next generation programmable power supplies and test solution.

You will learn:

- How incorporating advanced SiC reduces magnetics size due to high switching frequency

- Why investing in advanced SiC reduces costs for higher voltage (greater than 500V)

- How using advanced SiC contributes to better reliability and mean time before failure (MTBF)

- Date: Thursday, May 06, 2021

- Time: 11:00 AM Eastern Daylight Time

- Duration: 1 hour

Find more information about power semiconductors in Marketing in Power Electronics section of the website.